No need for any extra equipment or options

New Standard in Data Collection from CNC Machines!

MTConnect is a protocol designed for exchanging data between shop floor equipment and software applications used for monitoring and data analysis.

Benefits

Common

Platform

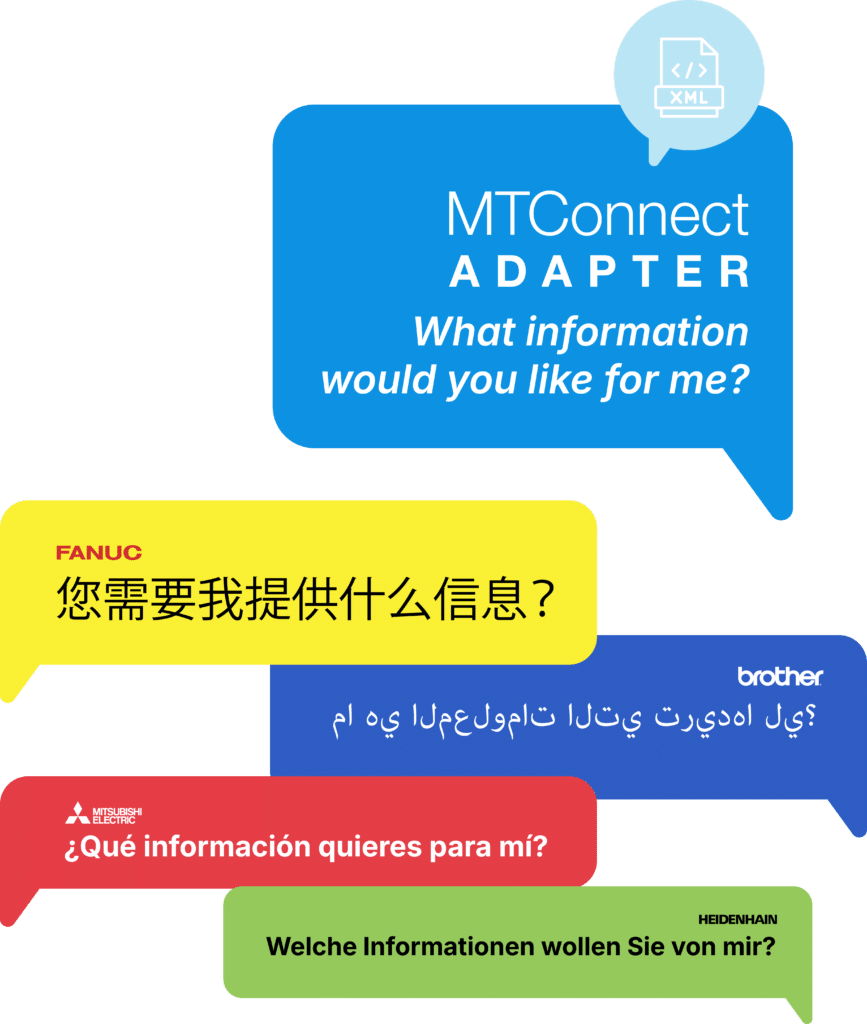

The main benefit of MTConnect is that it enables data from a varied range of machines to have common values, units, names and context.

Standard

Structure

Standardized vocabulary and semantics of the information models.

High Accessibility

Provides a read-only feature which prevents any inadvertent changes to the machine parameters.

Easy

Integration

Based on open internet standards like HTTP & XML which allows easy adoption.

Open

Source

Enables interoperability with multiple open standards like OPC UA, B2MMl, UMATI.

Simplify Data Collection

Device

PLC

Adapter

Agent

Application

Web Application / HMI

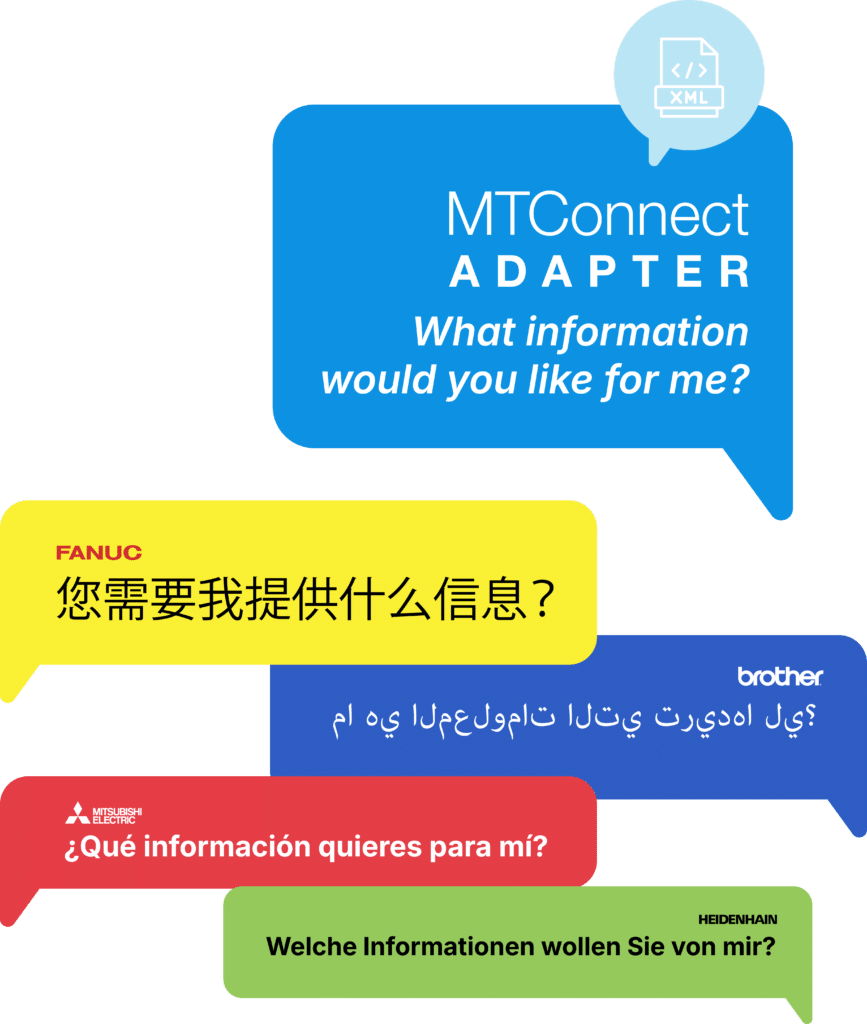

How it works?

It provides communication between the machine and the Agent. Your data is collected from your machines in your business via MTConnect Adapter and converted into a common language. You can access this understandable data with the help of SmartFactory Agent Service.

How it works?

It provides communication between the machine and the Agent. Your data is collected from your machines in your business via MTConnect Adapter and converted into a common language. You can access this understandable data with the help of SmartFactory Agent Service.

MTConnect Standardises Factory Device Data.

MTConnect is a manufacturing technical standard for retrieving process information from numerically controlled machine tools.

MTConnect Standardises Factory Device Data.

MTConnect is a manufacturing technical standard for retrieving process information from numerically controlled machine tools.

MTConnect Standard Has Three Sections.

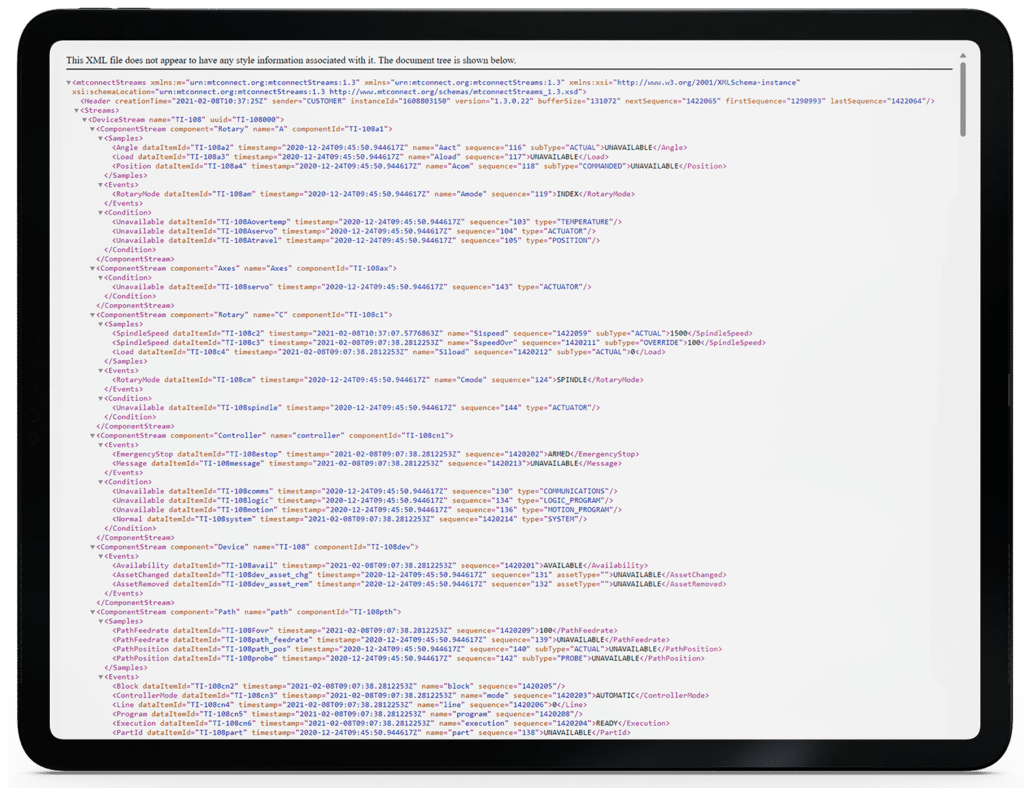

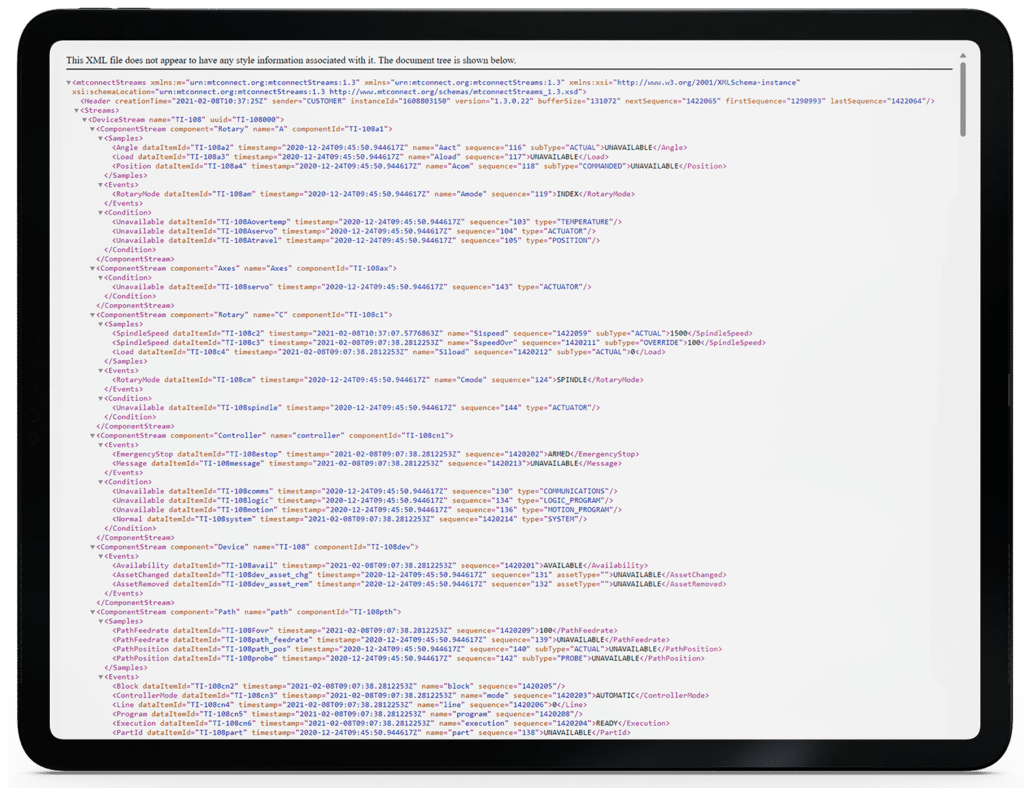

The first section provides information on the protocol and structure of the XML documents via XML schemas. The second section specifies the machine tool components and the description of the available data. The third and last section specifies the organization of the data streams that can be provided from a manufacturing device.

MTConnect is referred to as a read-only standard.

MTConnect is a protocol designed for the exchange of data between shop floor equipment and software applications used for monitoring and data analysis.

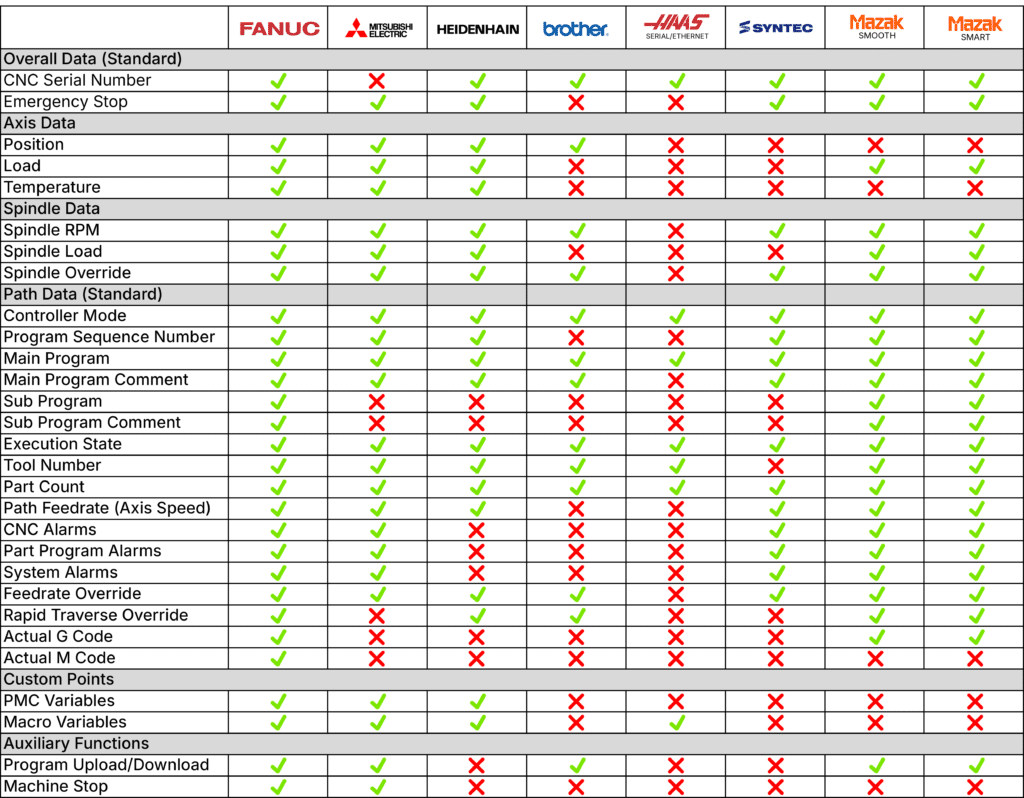

CNC Data Supported Through

MTConnect Server

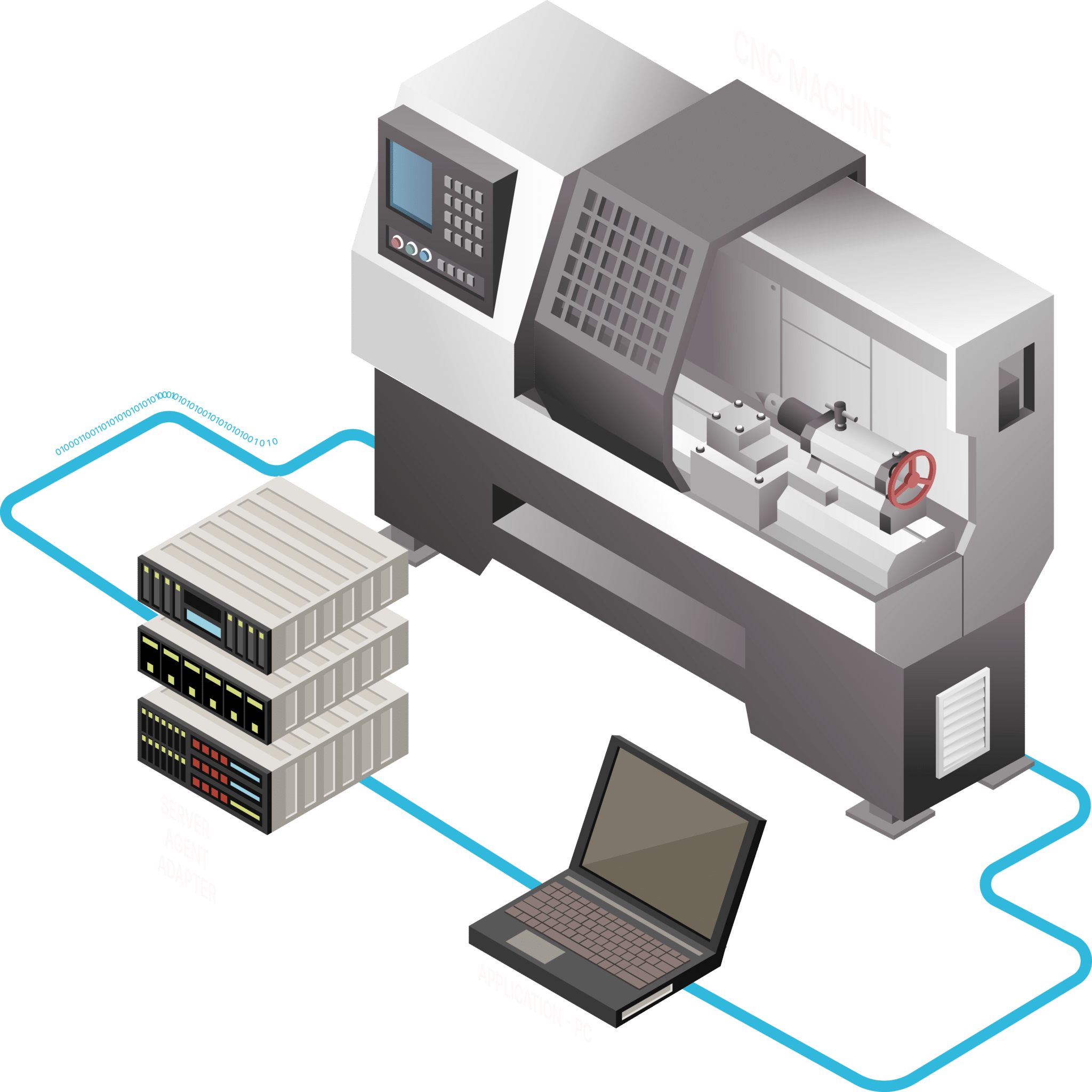

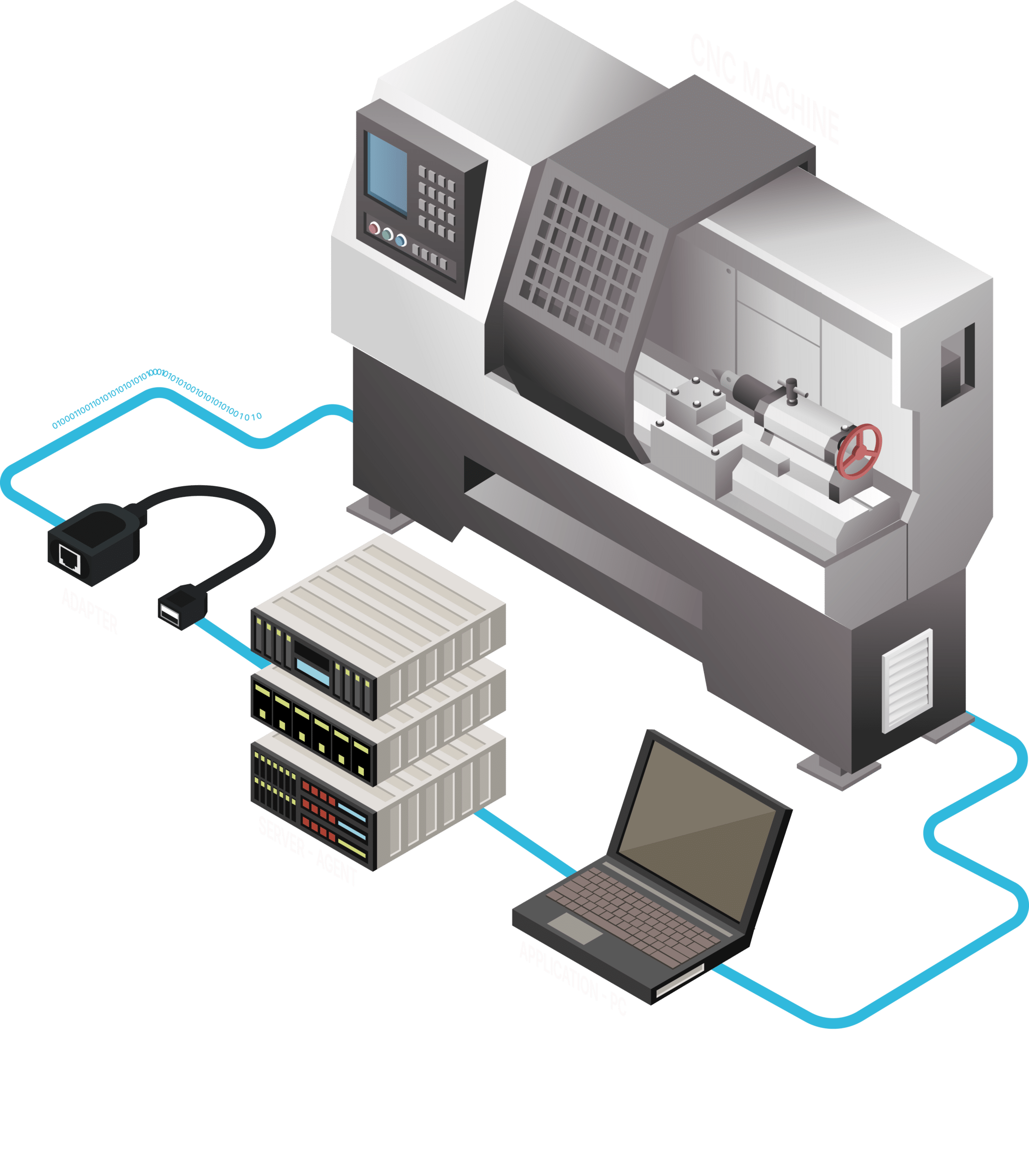

How does it work?

Plug & Play Infrastructure

Just connect an ethernet cable to your machines. Simply plug one end of the Ethernet cable into the ethernet port of your machine and the other end into any ethernet distribution point. This is all you need to do. You can add the rest yourself or get support from us.

Secure Data Transfer

With the MTConnect Adapter, the language of all machines is translated into a common language and the data is made meaningful. When your machine language is converted into a common language (XML) format, you can easily process data as you wish.

Easy Integration with Third Party Software

The MTConnect Adapter translates the machine language into a common language by networking the connection between the machine and the agent. You can access the machine data converted to XML format via SmartFactory Agent (Windows Service). Thanks to this software, you can receive all compatible machine data in your factory in the same format and easily integrate them into your upper software.

How does it work?

Plug & Play Infrastructure

Just connect an ethernet cable to your machines. Simply plug one end of the Ethernet cable into the ethernet port of your machine and the other end into any ethernet distribution point. This is all you need to do. You can add the rest yourself or get support from us.

Secure Data Transfer

With the MTConnect Adapter, the language of all machines is translated into a common language and the data is made meaningful. When your machine language is converted into a common language (XML) format, you can easily process data as you wish.

Easy Integration with Third Party Software

The MTConnect Adapter translates the machine language into a common language by networking the connection between the machine and the agent. You can access the machine data converted to XML format via SmartFactory Agent (Windows Service). Thanks to this software, you can receive all compatible machine data in your factory in the same format and easily integrate them into your upper software.